What are the effects of poor power quality?

The power quality of the energy given to your company and consumers is measured by how well it fits their requirements and expectations. Poor power quality can lead to a variety of issues, including equipment damage, malfunction, inefficiency, and increased expenses.

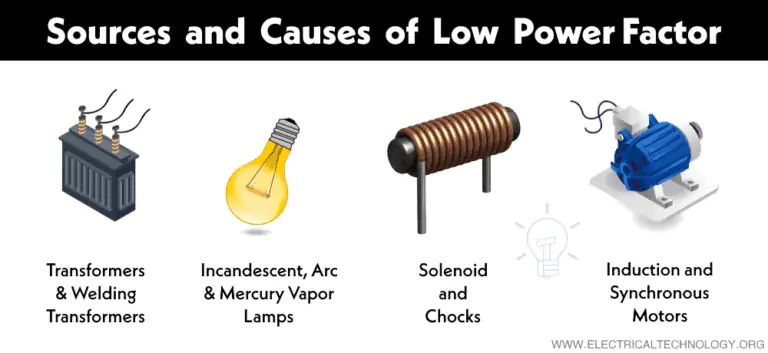

The most common causes of low power quality

Poor power quality can be caused by a number of factors, both internal and external to your firm. Changes in load demand, faults, switching, and non-linear loads all cause voltage variations such as sags, swells, spikes, and harmonics. Instability in the generating or transmission system, or an imbalance in the load, can generate frequency changes like as dips, surges, and flicker. Lightning strikes, switching, or short circuits are common causes of transients such as impulses and oscillations. Furthermore, neighboring sources of radiation, such as radios, mobile phones, or power lines, can cause noise such as electromagnetic interference (EMI) or radio frequency interference (RFI).

The most common consequences of insufficient power quality

Poor power quality may have a number of negative consequences for your company and consumers, including decreased equipment life and performance, increased energy consumption and expenses, decreased productivity and quality, and an increased risk of safety and environmental hazards. Overheating, insulation breakdown, component failure, or malfunction; utility losses, inefficiencies, or fines; downtime, mistakes, rework, or waste; or fires, shocks, or emissions.

How to Assess Power Quality?

To identify and diagnose power quality issues, important parameters of the energy provided to your firm and consumers must be measured and monitored. Voltage magnitude and waveform, current magnitude and waveform, frequency and phase angle, power factor and harmonics, and energy consumption and demand are all examples. To do this, you can employ a variety of instruments and technologies, including meters, sensors, and software. The values of the parameters are shown or recorded by meters such as voltmeters, ammeters, wattmeters, or power quality analyzers. Sensors such as current transformers, voltage transformers, or Rogowski coils convert the parameters into signals that meters or other devices can handle. Power quality software, for example, analyzes and visualizes data acquired by meters or sensors, producing reports or alarms.

How to Boost Power Quality?

To enhance power quality, solutions that address both the causes and effects of the problems must be implemented. This could include addressing the source of the problem, such as repairing faults, balancing loads, or filtering noise; protecting the equipment from the problem, such as installing surge protectors, voltage regulators, or uninterruptible power supplies (UPS); compensating for the problem, such as adding capacitors, reactors, or active power filters (APF) to improve power factor or reduce harmonics; and optimizing system design and operation, such as upgrading wiring, telecommunications, and data transmission.

How to Take Advantage of Power Quality?

Improving power quality may provide several advantages to your company and consumers, including higher equipment dependability and efficiency, lower energy consumption and costs, increased productivity and quality, and improved safety and environmental performance. Power quality is an important part of power engineering that has a big impact on your company and consumers. Understanding the causes and impacts of poor power quality, as well as implementing the appropriate remedies, will assist you in improving your power quality and reaping the benefits.