Strong Power: Static Var Generator SVG Introduction

Strong Power Electric’s SVG research and development began in 2006. In May 2007, the first generation of ZBSVG series products was developed based on the existing mature technology. The power of the whole machine is below 10M, and the voltage coverage level is below 10kV; The second generation of products began to be applied to the power industry, and the power level of the single machine was expanded to 12M; by November 2011, the third generation of SVG products of Strong Power Electric, the voltage level was raised to 35kV, and the capacity of the single machine was expanded to 50M, and it was widely used in new energy. , coal, metallurgy and other industries.

The key components of ZBSVG all adopt the latest fourth-generation chips imported from Germany, which have the characteristics of high junction temperature (150°C), good switching characteristics, strong over-current capability (10Ie), and supplemented by perfect protection and drive technology. The annual IGBT failure rate is less than 0.05%. In addition, the specially designed capacitor adopts German high-temperature metallized film, optimized internal parallel structure, ultra-low parasitic parameters ESL and ESR, good self-healing characteristics, rated temperature rise <11°C, strong ripple resistance, accelerated fatigue The test life (5% failure rate) is 18 years, and related products have passed TUV certification. Secondary components are all high-quality products such as relays, controllers, and PLCs from Siemens, ABB, and Schneider. One-time plug-in process is used for all plug-in, which realizes fast plug-in of components. The current capacity of the connector and the temperature under the rated current determine the reliability of this connection method. When selecting a connector, our company mainly considers the parallel connection of multiple connectors to increase the current margin and connection reliability. The nickel-plating process on the copper surface ensures that the surface layer will not be oxidized after long-term operation, the contact resistance is small, and the temperature rise at rated current is 8 degrees.

The ZBSVG product series has passed the type test of the National Electronic Control Distribution Equipment Quality Supervision and Inspection Center (Tianjin) and the State Grid Electric Power Research Institute (Nanjing). The certified specifications and models: 35kV voltage level 5Mvar and 24Mvar two specifications, 10kV voltage level There are two specifications of 2Mvar and 15Mvar.

The control software of ZBSVG series products has obtained intellectual property certification from the State Intellectual Property Office.

- Factory test: Over-current protection of power unit, trigger abnormal protection, over-voltage protection, over-temperature protection, communication abnormal protection, etc.

- Machine protection test: System overvoltage, system undervoltage, system overcurrent, abnormal system frequency (simulation), DC voltage bias protection, abnormal communication.

- Routine test: Hi-voltage test, functional test, stable operation, output power quality test, etc.

- Environmental test: generally includes salt spray testing, high and low temperature impact testing, humidity and heat alternating testing, and low air pressure testing when designing boards, power unit components, and complete machines. In addition, vibration testing for transportation is simulated at the national level two highway standards.

- ZBSVG series products all use single-phase reactors, which can effectively suppress the coupling between the three phases, improve the harmonic content of the output current, and have low noise and low loss.

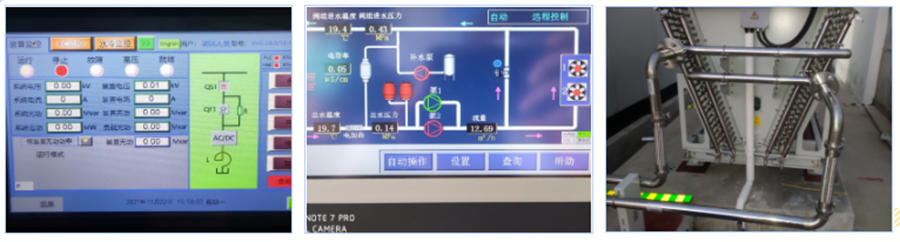

- The main control system uses 5 DSP chips plus 10 FPGA chips to form an array, which can effectively improve compensation accuracy, response speed, and overall performance.

- The pulse generation system uses multiple FPGAs. It can realize the expansion of the whole machine, performance upgrade, etc., and lays the hardware foundation for the realization of functions such as remote control and detection.

- High-speed optical fiber communication can not only realize high and low voltage isolation, but also has strong anti-interference ability and reliable communication.

- The response speed is fast, and it can complete the response to the system disturbance and complete the compensation within 5mS, while the response speed of the traditional supplementary method is above 40mS.

- Strong compensation ability, the compensation capacity is not affected by the system voltage, and has low voltage ride-through ability. The traditional compensation method decreases the compensation ability when the voltage drops, and increases the compensation ability when the voltage rises, which has a great negative impact on the power grid.

- Smooth and stepless compensation can realize real on-demand compensation, eliminate the classification of traditional compensation, group compensation mode, and eliminate over-compensation and under-compensation.

- Realize two-way compensation, one device can not only compensate inductive reactive power, but also realize capacitive reactive power.

- It occupies a small area, which is 1/3 of the traditional compensation method with the same capacity.

- The compensation has high safety, is not sensitive to the harmonics in the system, and will not generate resonance or resonance with the system.

- High degree of intelligence, self-starting, self-resetting, remote monitoring and management, truly unattended.

- There is no inrush current when switching on, and the ramp loading mode is adopted, and the ramp unloading mode is adopted when stopping.