In modern industrial production, power quality plays a critical role in ensuring the stable operation of manufacturing equipment and optimizing energy efficiency. As factory automation continues to advance and renewable energy systems become increasingly prevalent, conventional reactive power compensation methods are proving inadequate for contemporary industrial demands. The Static Var Generator (SVG), an advanced flexible AC transmission system device, has emerged as the optimal solution for reactive power compensation in industrial power systems. This technology demonstrates particularly remarkable technical and economic advantages in facilities that utilize hybrid power systems combining traditional grid electricity with solar photovoltaic generation.

In industrial facilities, inductive loads like motors, transformers, and frequency converters produce significant lagging reactive power during operation, leading to a reduced power factor and subsequent operational challenges. A low power factor not only increases line losses and voltage drops, compromising power supply efficiency, but also diminishes the effective capacity of transformers and distribution lines, potentially hindering stable equipment performance. Moreover, utilities typically mandate a minimum power factor of 0.9, with non-compliance resulting in financial penalties. Voltage fluctuations and poor power quality may further disrupt sensitive instruments and critical equipment. Implementing proper reactive power compensation is therefore essential for enhancing energy efficiency, lowering operational expenses, and maintaining reliable equipment performance in industrial settings.

An increasing number of factories are adopting rooftop solar photovoltaic (PV) systems, creating a power supply model based on “self-generation and self-consumption, with surplus electricity fed into the grid.” However, the intermittent and volatile nature of PV generation introduces new power quality challenges to factory power grids. Static VAR Generators (SVGs) have emerged as a key solution to these issues due to their fast dynamic response capabilities.

The coordinated operation of Static VAR generator SVGs and PV systems is primarily reflected in three aspects: voltage stability control, power factor correction, and harmonic suppression. When sudden fluctuations in PV output cause voltage variations at the grid connection point, Static VAR generator SVGs provide millisecond-level dynamic reactive power support. Additionally, while PV inverters operate at unity power factor, Static VAR generator SVGs independently handle the system’s reactive power compensation needs. Furthermore, Static VAR generator SVGs equipped with active filtering capabilities can effectively mitigate harmonic distortion caused by PV systems.

This collaborative approach not only enhances the grid-friendliness of PV systems but also optimizes overall power quality within the factory. Through intelligent Static VAR generator SVG regulation, factories can maintain a stable and reliable power supply while maximizing solar energy utilization—achieving both economic and environmental benefits. Even when PV systems are inactive at night, Static VAR generator SVGs continue to provide reactive power compensation, enabling 24/7 power quality management.

Key points of system design for Static VAR generator SVG selection

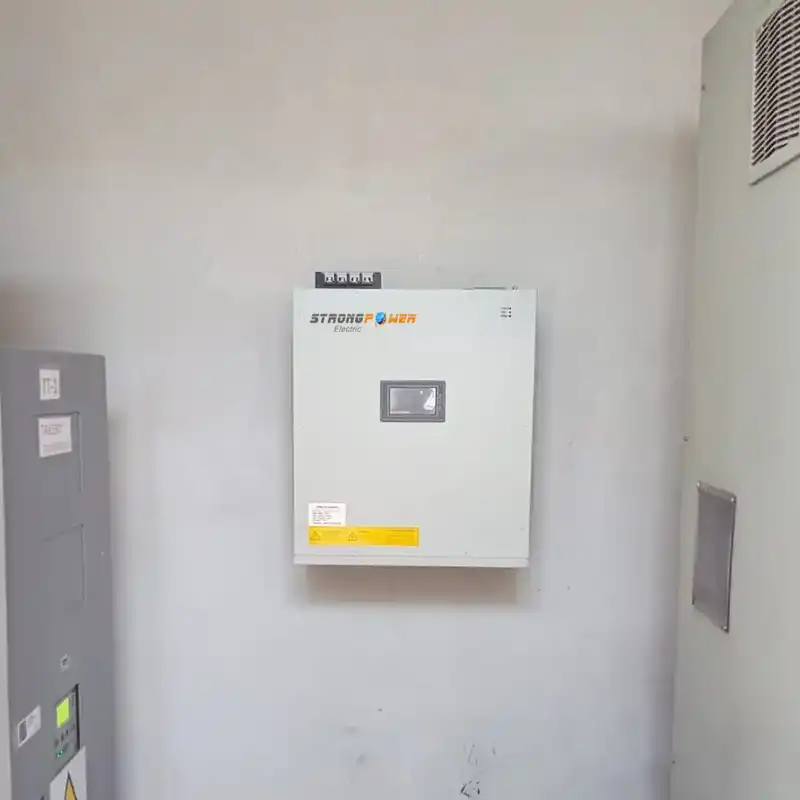

The system design for Static VAR generator SVG selection should holistically account for factory load profiles, PV capacity, and grid specifications to appropriately size compensation capacity and optimize placement. Typical installations are positioned at distribution bus terminals or PV grid interconnection points to maximize reactive power compensation efficiency and ensure system stability.

- For centralized compensation: Install the compensation equipment on the low-voltage bus side of the distribution room.

- For local sensitive loads: Install compensation devices near the load.

- For large photovoltaic systems: A dedicated Static VAR generator SVG should be installed at the grid connection point.

Static VAR generators (SVGs), as the core equipment for power quality management in modern industrial facilities, not only address the limitations of traditional reactive power compensation but also play a pivotal role in enabling grid integration of distributed energy sources like solar photovoltaics. Amidst the dual trends of energy transition and smart manufacturing, the synergistic application of Static VAR generator SVGs with photovoltaic systems is becoming an essential feature of industrial plants, offering reliable solutions for enterprises to achieve sustainable production and energy efficiency. During power system planning, factories should integrate Static VAR generator SVG technology into their overall design to maximize its comprehensive benefits, including reactive power compensation, voltage regulation, and renewable energy integration capabilities.