Oil drilling industry: high voltage static var generator STATCOM

In the drilling project of Jiangsu Oilfield, the reactive power compensation technology of the oilfield was successfully put into production, and all equipment parameters were operated normally, which successfully solved the difficult problem of the severe impact of reactive power fluctuation on power supply reliability during the fracturing and production of the oilfield.

Because the power supply system of the drilling project is too long and the load is mainly concentrated at the end of the line, the voltage of the end line is low, which directly affects the fracturing progress of the oil field. In order to improve the terminal voltage and transmission power of the fracturing line, meet the needs of production, and solve the problem that the violent fluctuation of reactive power in the process of shale oil exploitation has a bad impact on the reliability of power supply, ZBSVG high voltage static var generator STATCOM adopts instantaneous reactive power theory control technology, FFT fast harmonic calculation technology and high-power IGBT drive technology, with high reliability, easy operation and high performance as its design objectives, It can rapidly and continuously provide capacitive or inductive reactive power, and realize various control modes such as constant assessment point reactive power, constant assessment point voltage, constant assessment point power factor, and comprehensive compensation.

Equipment model: ZBSVG-C6.0/35-O

Rated voltage: 35kV

Product form: outdoor container type

Cooling mode: forced air cooling

ZBSVG high voltage static var generator STATCOM can not only automatically compensate reactive power, but also dynamically compensate harmonics at the same time. To ensure the stable operation of the power system, it can enhance the power transmission capacity, reduce power loss, compensate reactive power, control harmonics, suppress flicker, stabilize the grid voltage, balance the three-phase system, change the damping characteristics of the system, and improve the stability of the system.

Strong electric carried out an in-depth analysis of the installation and commissioning work and held an on-site work coordination meeting. In order to ensure the successful operation of the equipment, the company formulated a detailed engineering plan in advance, organized all personnel to familiarize themselves with the equipment operation process and risks, distributed the power transmission, commissioning, and installation tasks, and implemented the risk control measures to every person on the site to ensure that everything is safe. Ensure the efficient and smooth operation of the equipment.

Strong Electric ZBSVG high voltage static var generator STATCOM oilfield shale oil drilling project

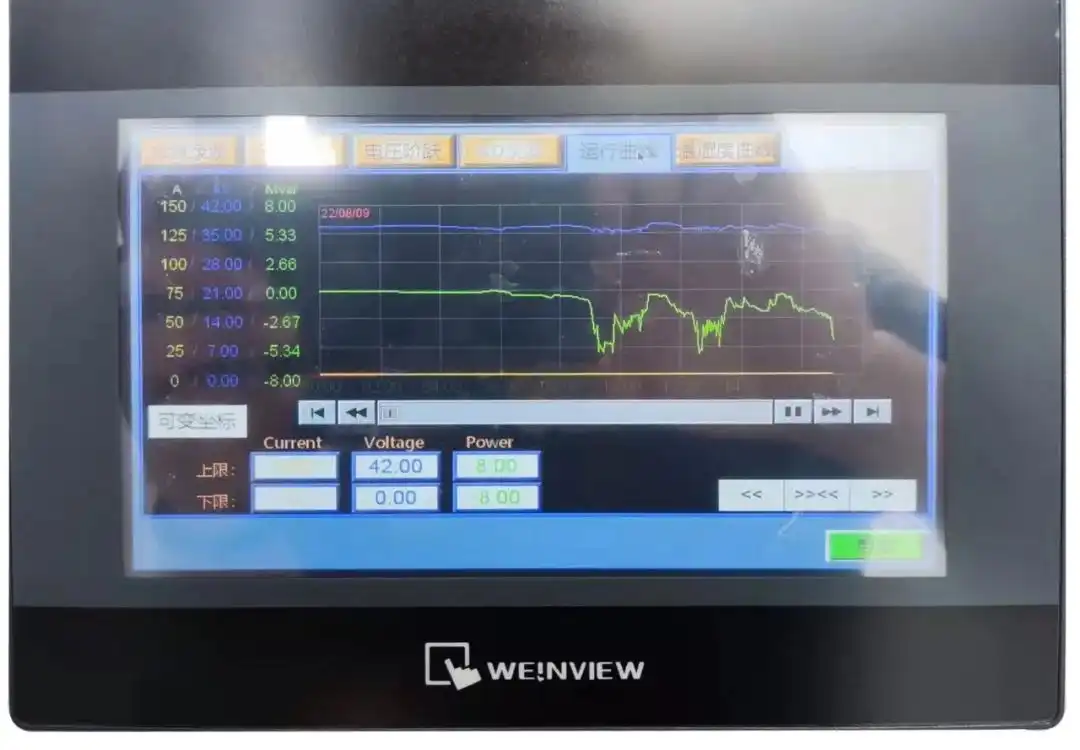

Equipment operation curve

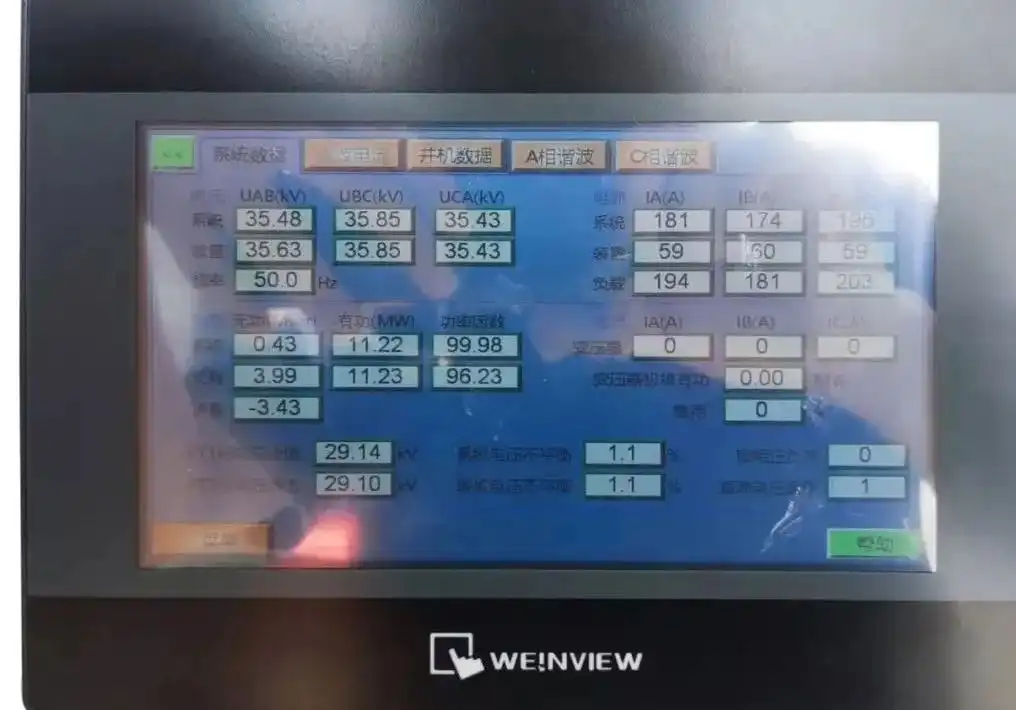

System data monitoring