In recent years, sustained and rapid economic growth has made automobiles an essential mode of transportation for daily commuting. Concurrently, the widespread adoption of power electronic equipment in automotive manufacturing has imposed stricter power quality requirements on factory distribution systems. This paper first elaborates on the necessity of harmonic suppression in the automotive manufacturing sector, with a focused analysis of the operational and harmonic characteristics of spot welding machines—a typical harmonic source. Subsequently, it examines the significance of harmonic control technology for automotive manufacturers. Finally, the study explores future trends in harmonic suppression technology and active harmonic power filters.

Analysis of Harmonic Control Demand in the Automobile Industry

The Impact of Harmonics on Automobile Manufacturing

In an ideal power distribution system, electricity is supplied as a standard 50Hz (power frequency) sine wave, varying only in phase and amplitude. However, nonlinear loads—such as motors, power electronic devices, and inverters—generate harmonics, which are integer multiples of the power frequency (non-integer multiples are interharmonics). These harmonics distort voltage and current waveforms, transforming the sine wave into a non-sinusoidal wave.

The automobile manufacturing industry relies heavily on nonlinear and impact loads, including welding machines, stamping presses, cutting machines, cranes, and inverters. The harmonics produced by these loads are characterized by rapid fluctuations and high amplitudes, making them difficult to control. Beyond disrupting normal production, they can severely damage equipment, leading to significant financial losses.

Conventional reactive power compensation devices, which primarily use capacitors and reactors, play a crucial role in power systems. However, their electrical properties make them susceptible to harmonic resonance, often resulting in abnormal overheating or even failure. Numerous case studies demonstrate that such issues not only increase maintenance and replacement costs but can also trigger complete distribution line failures due to capacitor breakdowns, leading to further economic losses.

Additionally, most on-site distribution systems employ thyristor-based automatic switching compensation devices. While thyristors are known for their longevity, their high sensitivity makes them vulnerable to minor grid fluctuations. Under harmonic interference, their rapid response and high-frequency switching—normally an advantage—become a drawback. Harmonics force thyristors to switch excessively, far beyond normal operational rates, drastically reducing their lifespan. This not only negates their durability but also escalates maintenance expenses for companies.

The Role of Harmonic Control

The primary function of harmonic control is to mitigate harmonic interference in power systems, ensuring the stable and efficient operation of electrical equipment. Its key benefits can be summarized in three aspects:

Targeted Harmonic Mitigation – Harmonic control addresses specific harmonic-related risks, such as neutralizing third harmonics in the neutral line to prevent overload or suppressing high-frequency harmonics to avoid resonance with capacitor banks, thereby safeguarding critical equipment.

Enhanced Power Quality – By employing advanced technologies like active filters, harmonic control significantly improves power quality in industrial settings. This is particularly crucial for precision manufacturing processes (e.g., stamping and welding), where harmonic interference can cause defects like weak welds or incomplete joints. Effective harmonic suppression minimizes such issues, boosting production yield.

Optimized Power Environment – A clean power supply ensures stable operating conditions for all connected equipment. This not only extends machinery lifespan but also enhances production continuity and reliability, delivering substantial economic value to enterprises.

2.1 Working Characteristics of Spot Welding Machine

In the automotive manufacturing industry, spot welding technology has been widely adopted due to its superior welding performance and compatibility with mechanical automation. Common spot welding equipment includes portable standalone welders, fixed welding production lines, and robotic welding systems. These devices exhibit distinct dynamic characteristics during operation: the input current surges to full load instantaneously during arc initiation and rapidly drops to near zero after arc extinction, resulting in frequent load transitions between no-load and full-load conditions. Notably, the diode rectifier circuit in inverter welding machines introduces significant harmonic components into the input current. The emergence and dissipation of these harmonics occur within just a few cycles, with transient changes on a millisecond timescale. This operational behavior not only causes drastic fluctuations in input current amplitude but also leads to dynamic variations in the total harmonic distortion rate, imposing complex effects on the power system.

2.2 Harmonic Characteristics Analysis of Spot Welding Machine

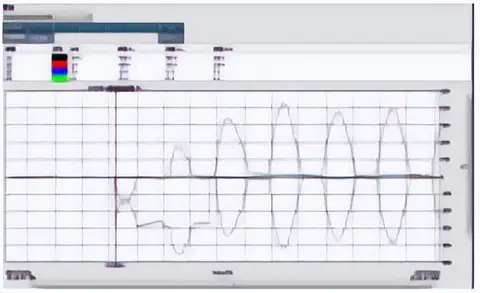

The low-voltage power supply system in welding workshops features a complex structure, primarily serving large-scale spot welding and stamping equipment. To investigate the harmonic characteristics of welding machines during operation, a typical unit was selected for dynamic testing. Figure 1 illustrates the operational current waveform of the spot welding machine after startup.

Analysis of Figure 1 reveals severe current waveform distortion: the A-phase current exhibits an extended plateau-like trough, while the B-phase current displays multiple peak features.

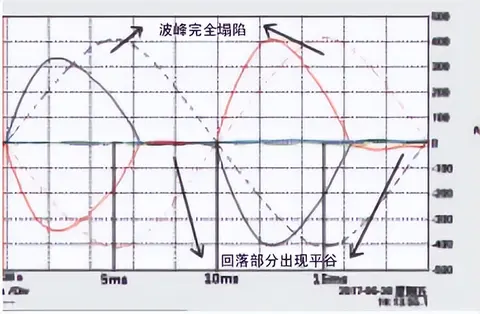

Figure 2 compares the welding machine’s current waveform with a standard sine wave (represented by a dashed line, which follows an ideal pattern: reaching a positive peak at 5 ms, crossing zero at 10 ms, peaking negatively at 15 ms, and completing a full cycle at 20 ms). Under ideal conditions, the current waveform should transition smoothly. However, actual measurements demonstrate significant deviation from the standard sine wave: during the 5 ms standard peak interval, the welding machine’s waveform remains in a descending phase, forming a prolonged zero-current plateau. This comparison conclusively confirms that the welding machine current contains substantial harmonic components, leading to severe waveform distortion and notable impacts on the power system.

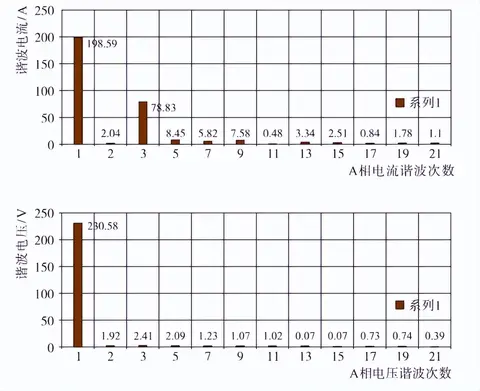

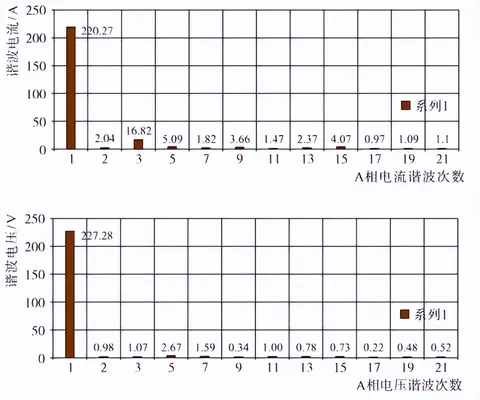

The harmonic spectrum analysis in Figure 3 further illustrates the harmonic distribution characteristics: the A-phase current harmonics are predominantly 3rd-order, followed by 5th, 7th, and 9th harmonics, while voltage harmonics primarily consist of 2nd, 3rd, and 5th-order components.

2.3 Harmonic Control Solution for Spot Welding Machines

Given the instantaneous impact load characteristics of spot welding machines, a harmonic control device with rapid response capability is essential. The Active Power Filter (APF), leveraging IGBT high-power devices and high-frequency switching technology, enables real-time tracking and compensation of harmonic currents. Additionally, it provides dynamic compensation for impact loads, demonstrating exceptional effectiveness in harmonic suppression for spot welding applications.

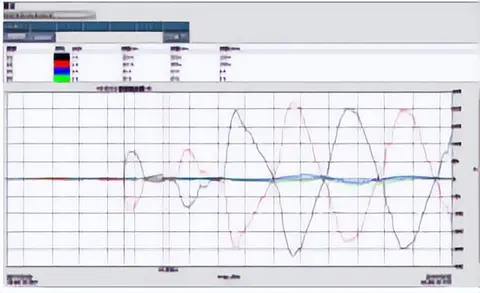

Figure 4 compares the current waveforms before and after APF implementation. The compensated current closely approximates a standard sine wave, with smooth transitions at peak and zero-crossing points, eliminating waveform distortion entirely. This confirms the effective filtration of harmonic components.

Figure 5 presents harmonic current and voltage spectra analysis. The harmonic current bar chart indicates complete elimination of the 3rd harmonic, along with significant attenuation of remaining harmonics. Similarly, harmonic voltage content is substantially reduced, particularly the previously dominant 2nd and 3rd harmonics, which are now effectively suppressed.

Field validation confirms that the APF fully adapts to the complex operational conditions of welding workshops, capable of real-time tracking and compensating for transient harmonic currents. Post-treatment results show near-complete elimination of welding machine harmonics, along with excellent suppression of grid harmonic voltage. The overall performance meets the targeted objectives.

Key Features of the Strong Power APF Active harmonics Power Filter:

- Advanced Digital Control: Utilizes a DSP+FPGA full digital control architecture for fast response, stable performance, and reliable algorithms.

- Dual Compensation Capabilities: Combines harmonic compensation (2nd–51st full-band or selective harmonics) and reactive power compensation.

- Comprehensive Protection: Integrated safeguards including bridge arm overcurrent protection, DC overvoltage protection, and temperature protection.

- Modular & Scalable Design: Compact, space-saving structure for easy installation, maintenance, and future expansion.

- User-Friendly Interface: Features a 7-inch color touchscreen for intuitive parameter configuration and device control.

- Enhanced Grid Stability: Equipped with a dedicated output filter to suppress high-frequency ripple interference.

- Parallel Operation Support: Enables multi-unit parallel operation for high-capacity current output requirements.