As a vital foundational industry in the national economy, the paper industry’s products find extensive applications across diverse sectors including packaging and printing, cultural goods, and healthcare. Nevertheless, being a typically energy-intensive sector, paper manufacturing enterprises have long grappled with three major technical challenges in their power systems: low power factor, severe harmonic pollution, and frequent voltage fluctuations.

Why are static VAR generators(STATCOM) necessary in paper mills?

In the production process, papermaking enterprises employ numerous nonlinear load devices—including inverters and rectifiers (such as chlorine dioxide rectifiers and chlor-alkali rectifiers)—resulting in severe harmonic pollution in the power grid, with the 5th and 7th harmonics being the most prominent. Monitoring data reveal that the 5th harmonic content exceeds the national standard limit by more than fivefold, accompanied by noticeable power quality issues such as voltage flicker, three-phase imbalance, and overvoltage/undervoltage. These abnormal operating conditions not only lead to additional losses in power transmission and distribution equipment but also prompt power regulatory authorities to issue mandatory rectification notices to affected enterprises.

The cascading effects of harmonic pollution are particularly severe: it not only significantly reduces power utilization efficiency but also causes abnormal heating in electrical equipment, increased mechanical vibration, accelerated insulation material aging, and—in extreme cases—equipment burnout, drastically shortening the lifespan of critical machinery. Consequently, establishing an effective harmonic mitigation strategy is imperative to ensure the safe and stable operation of the power system.

Why is static VAR generators(STATCOM) the preferred solution?

The static VAR generator (SVG) has emerged as the preferred reactive power compensation solution for paper mills, owing to its superior performance in response speed, compensation accuracy, harmonic suppression, and energy efficiency compared to conventional methods like thyristor-switched capacitors (TSC) and static VAR compensators (SVC).The following is a detailed technical comparison analysis:

-

Response speed: millisecond-level dynamic compensation

| Compensation Method | Response Time | Application Scenario | Paper Mill Requirements |

| TSC | 20~40ms (Mechanical Switching) | Slow-varying loads | Unable to handle rapid impact loads like pulpers and VFDs |

| SVC | 20~50ms (Thyristor Controlled) | Medium-speed load fluctuations | Insufficient for dryer section voltage flicker suppression |

| SVG | <10ms (Full-control IGBT) | High-speed impact loads, precision voltage regulation | Perfectly matches instant reactive power demands of paper machines and VFDs |

-

Compensation accuracy: stepless continuous adjustment

| Compensation Method | Regulation Type | Control Characteristics | Advantages for Paper Mills |

| TSC | Stepwise Switching | Discrete capacitor bank switching | Simple structure, low cost |

| SVC | Quasi-continuous (TCR+FC) | Thyristor-controlled reactors with fixed capacitors | Medium precision, some delay |

| SVG | True Continuous Regulation | IGBT PWM vector control | Seamless reactive power adjustment without over/under compensation |

-

Harmonic control: compatible with harmonic suppression

| Compensation Method | Harmonic Interaction | Harmonic Mitigation Capability | Paper Mill Application Impact |

| TSC | May amplify harmonics (resonance risk with capacitors) | None – requires separate filters | Worsens existing 5th/7th harmonics from VFDs |

| SVC | Generates low-order harmonics (TCR-induced) | Limited – needs additional filters | Increases THD by 3-5% without filters |

| SVG | Harmonic-neutral operation | Built-in active filtering (optional) | Reduces THD to <5% (meets IEEE 519) |

-

Energy efficiency and reliability

| Parameter | TSC/SVC | SVG | Advantage for Paper Mills |

| Efficiency | 92-95% (capacitor/reactor losses) | 98%+ (IGBT high efficiency) | Reduces energy waste in 24/7 operations |

| Footprint | Large (multiple capacitor banks) | Compact (modular design) | Saves valuable factory space |

| Maintenance | High (regular capacitor replacement) | Minimal (solid-state design) | Eliminates 3-5 annual maintenance stops |

| Lifespan | 5-7 years (component degradation) | 10-15 years (no moving parts) | Long-term ROI improvement |

| Cooling | Air-cooled (limited capacity) | Liquid/air hybrid options | Better for hot pulp mill environments |

-

Adapt to complex industrial environment

Three-phase unbalance control: SVG can independently adjust the reactive power of each phase to solve the imbalance problem caused by single-phase large load (such as dryer) in paper mills.

Anti-interference ability: SVG adopts DSP+FPGA digital control, which is more adaptable to the high electromagnetic interference environment of paper mills than TSC/SVC analog circuit.

Intelligent expansion: Supports linkage with the DCS/EMS system in the factory to achieve remote monitoring and energy efficiency optimization.

Strong Power solutions for reactive power compensation and harmonic control

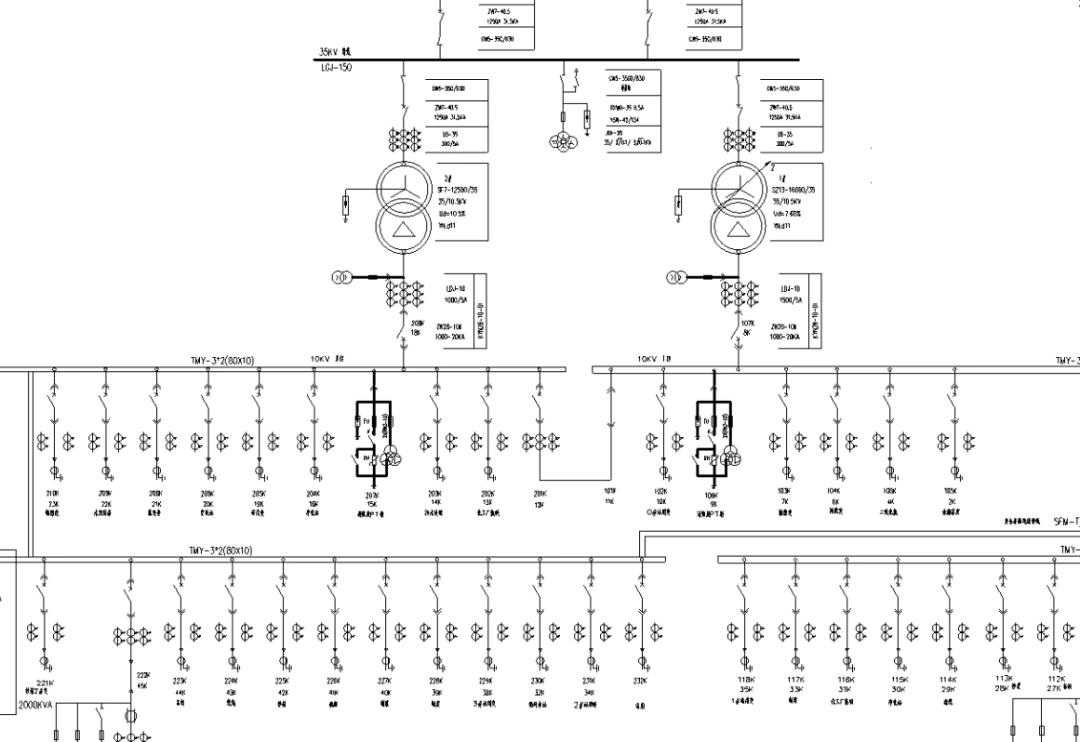

The paper mill’s 35 kV power grid is supplied by two main transformers, which are powered by a 10 kV bus operating in a one-in-use, one-standby configuration. The 10 kV bus supplies nearly 60 branch circuits and is supported by two independent generators. Among the connected equipment—including chlorine dioxide rectifiers, chlor-alkali rectifiers, and low-voltage frequency converters—the 5th and 7th harmonics are predominant, with the 5th harmonic exceeding permissible levels by more than five times. Due to this violation, the power company has issued a mandatory order requiring corrective action within a specified timeframe.

To address the 5th harmonic issues in the power grid, this project proposes the installation of a 10 kV, 5 MW Static Var Generator (SVG) on the 10 kV busbar. By real-time monitoring of grid voltage, grid current, and load current, the SVG will dynamically and continuously adjust reactive power compensation, ensuring stable, efficient, and high-quality power grid operation.

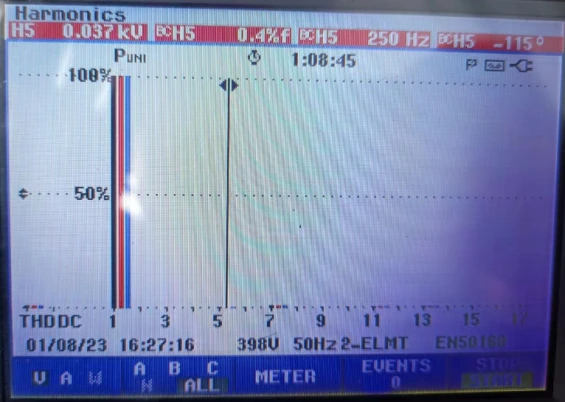

After commissioning the device, the 5th harmonic levels across all power supply lines were significantly reduced.

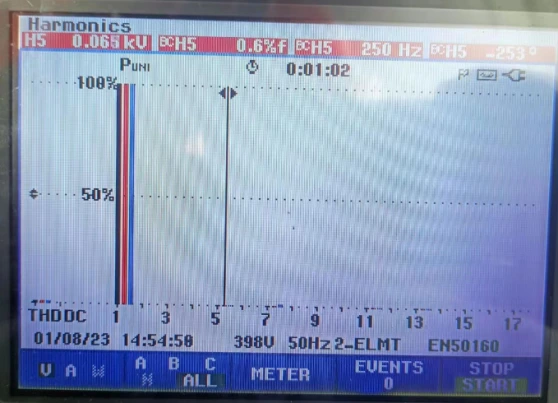

Compensating for pre-voltage harmonics

Compensated after voltage harmonics

Why Choose Us?

We specialize in high-performance SVG solutions featuring millisecond-level dynamic compensation, integrated harmonic suppression, and ultra-high reliability. Our technology helps clients stabilize voltage, enhance energy efficiency, and lower operational costs. Contact us today for a customized power quality analysis and tailored solution design!