Coal chemical industry: high voltage dynamic reactive power compensation device

Background of the project:

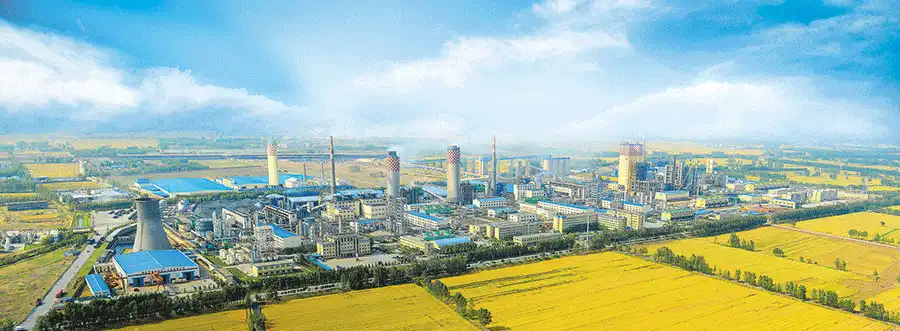

Strong Power Electric Co., Ltd. produces high voltage dynamic reactive power compensation devices for coal chemical tail gas with an annual output of 1 million tons of liquid carbon dioxide, 20,000 tons of ammonium bicarbonate and 10,000 tons of industrial ammonia water. The total investment of this project is 134 million yuan. The main construction content includes carbon dioxide compressor plant, ice machine plant, CO₂ plant circulating water pump room, dry ice plant, ammonium bicarbonate warehouse, etc., with a total area of 4480.82 square meters; outdoor projects include floor paving, plant road paving, land greening and reserved land, etc. Plant equipment installation includes ammonium bicarbonate and ammonia water recovery device, wastewater and ammonia water tank area, liquid CO2 product tank area, outdoor purification device area, raw gas pre-cooling buffer equipment area, etc.

After the completion of the project, 1.011 million tons of carbon dioxide emissions can be reduced each year. To a certain extent, it can solve the problem of industrial tail gas emissions from chemical projects, reduce air pollution, increase economic, social and environmental benefits, and realize comprehensive utilization of resources.

Load analysis:

CO2 production equipment: CO2 compressors, ice machines, pumps and other equipment, all of which use high-power motor drives. The starting and unloading of the motor will generate a large amount of reactive power demand. The direct output of reactive power to the grid will occupy the effective load capacity of the grid, increase the loss of the transformer and reduce its service life. Line loss and transformer loss make the power factor of the entire enterprise power grid also decrease. The increase of non-linear loads has brought serious harmonic problems, affecting the safe operation of the power grid and reducing production capacity. The transmission of a large amount of reactive current back and forth on the power grid will generate additional transmission loss, increase electricity charges, and accelerate the aging of the line. In addition, the power factor that is too low will also lead to fines from the power supply bureau, resulting in unnecessary electricity expenses.

Solution:

According to the analysis of on-site load characteristics, the CO2 compressors, ice machines, and pumps used in this project have a large starting current, which reaches the maximum value in an instant, generating a large amount of reactive power and causing grid voltage fluctuations. After the customer adopts the ZBSVG 10KV high-voltage dynamic reactive power compensation device, it can compensate the reactive power of the system in real-time, ensure the stability of the system, ensure the safe operation of the equipment, reduce the damage caused by equipment shutdown, improve the power factor, and thus increase the service life of the equipment, Reduce power adjustment fines.

System composition:

ZBSVG high voltage dynamic reactive power compensation device(STATCOM) is mainly divided into three parts: control cabinet, power cabinet, and reactor cabinet (if it is an air-core reactor, there is no cabinet). the power cabinet has achieved great unity, which is convenient for the expansion and stability of production capacity.