Smart Power Fault Indicator System Application of in Overhead Line

Project Background

In many regions, power lines are widely dispersed over large distances. When a fault occurs in the power line, traditional fault locating systems often struggle with low accuracy, making the fault identification process difficult and time-consuming. Manual inspection methods are inefficient, and the longer the power outage lasts, the greater the economic impact on society.

Industry Requirements

- Improved Fault Locating Accuracy: Enhance the precision of fault detection and improve communication efficiency between the field and the control center.

- Data Optimization: Enhance data filtering capabilities to minimize unnecessary data transmission.

- Data Security: Implement a VPN channel for data encryption to ensure secure communication.

Application Overview

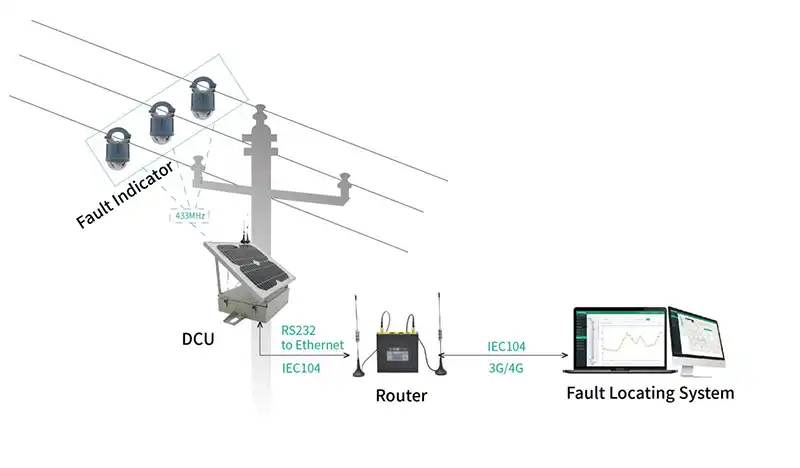

The proposed solution for fault detection in overhead power lines utilizes a Fault Indicator System, which includes both a router and remote fault indicators deployed on-site. The system consists of the following components:

Acquisition Units: These on-site units collect power data and transmit it via 433 MHz to an aggregation unit.

Aggregation Unit: The aggregation unit receives the data from the acquisition units and is connected to a Router via an RS232 to Ethernet port.

Data Transmission: The industrial router uses the IEC 104 protocol for transparent data transmission, sending the information over a 3G/4G network to the fault locating platform.

Fault Detection: In the event of a fault, the system quickly and accurately pinpoints the location, allowing the operation and maintenance personnel to swiftly address and resolve the issue, minimizing downtime and reducing economic losses.

This solution improves fault locating accuracy, streamlines communication, and ensures the efficient and secure transmission of power data, enabling faster fault resolution and enhanced grid reliability.